Over the years, LED Light Sheet has been specified by architect and design practices for a wide range of projects and we’re extremely proud of our light panel’s reputation as being a reliable, high performance lighting system. The key to LED Light Sheet’s success starts at the grass roots of the product with how the light panel is manufactured. Unique in its construction, LED Light Sheet features a number of patented processes that come together to create an innovative lighting solution.

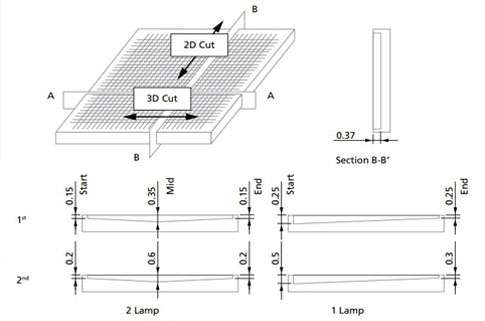

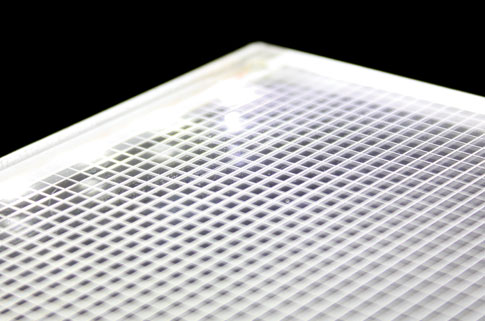

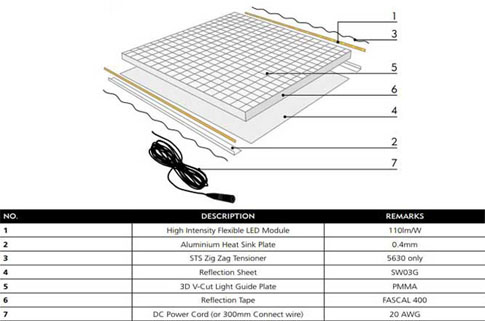

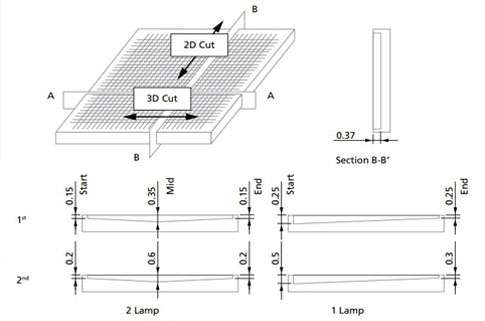

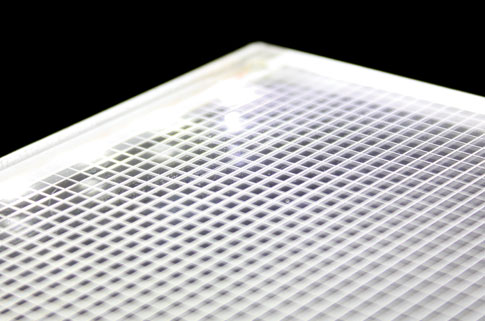

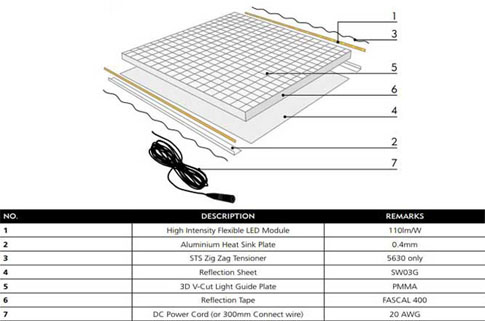

Forming the basis of the light panel and sourced for its rigidity and light transmission properties, the light guide plate (LGP) is manufactured from clear PMMA acrylic. The material is engineered with an etched design using a patented, 3D V-Cutting technology to create multiple, uniformed grooves.

The engraved pattern is clever in design as the matrix grid acts as a vehicle to transport light from the panel’s embedded LEDs, spreading light evenly across the entire surface of the light sheet. This product engineering ensures bright, homogenous illumination is delivered throughout the LED Light Sheet without any risk of ‘dark spots’ or drop in light.

Helping to facilitate projects, LED Light Sheet is a highly versatile lighting system, which can accommodate different requirements due to its low running temperature and made to measure properties.

Our light panel is manufactured with thermally managed LEDs as standard, which are securely embedded inside the clear acrylic sheet. Ensuring the light sheet runs cool to the touch, the light guide plate is created with a unique, aluminium heat sink that allows heat generated by the LEDs to find a path and dissipate, preventing the LEDs from burning out. The cool running temperature of LED Light Sheet makes the light panel ideal for low level installations and applications such as display shelves for retail design, helping to accommodate heat sensitive products. The longevity of the light panel boasts an impressive 50,000 hours, which equates to roughly 11 years if the LED unit is running for 12 hours per day.

Another main benefit about Applelec’s LED Light Sheet is that the light panel is created to bespoke specification and we have been privy to some imaginative and unique creations over the years, such as recreating a bird emblem for a well-known, luxury vodka brand. Along with unusual shapes, our light panel is available in sizes up to 3000 x 1500mm, where large light panels have been used to create some truly inspiring architectural light installations, such as the 6.5m tall fireplace for The Corniche project.

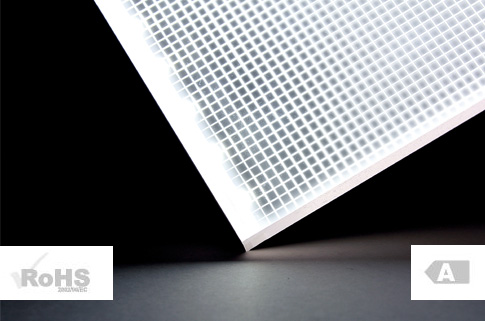

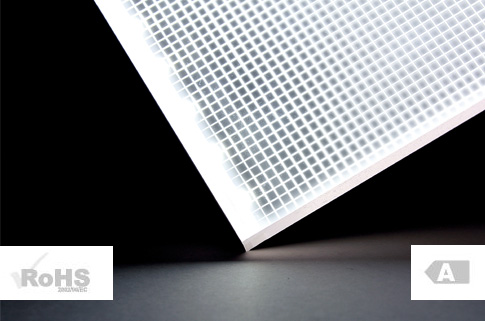

Green energy will continue to be an important factor for designers specifying lighting and Applelec’s LED Light Sheet carries an EPC A Band rating as the LEDs consume 70% less power than T5 fluorescent lighting and up to 30% less energy than CCFL. Other assurances with our light sheet is that the lighting system is RoHS complaint as LED Light Sheet does not contain any mercury or hazardous material.

Applelec’s LED Light Sheet is manufactured in the UK at our West Yorkshire factory.

Take a look at our Resources page for more information on Applelec's light panel.

If you found this interesting, feel free to tweet about it.